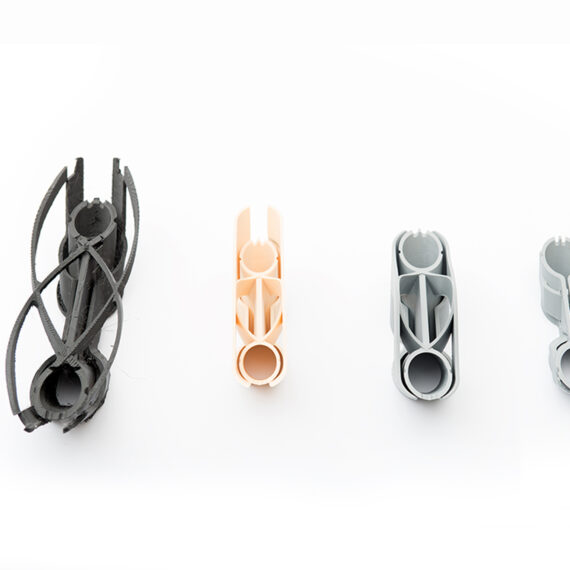

The benefit of

additive manufacturing

A new approach, that focuses on flexibility and efficiency instead of just preparedness.

Additive manufacturing is what is commonly called 3D printing. This technology brings different new opportunities in terms of production and value chains. Firstly, things can be created with little machinery, allowing decentralized production. Secondly, this process, deepening on the type of 3D printing, just takes the effectively needed amount of material. Thirdly, it allows us to quickly prototype, test and improve. These three aspects are the pillars of the concept embodied by crutches.