The setting and aim of

the overarching project

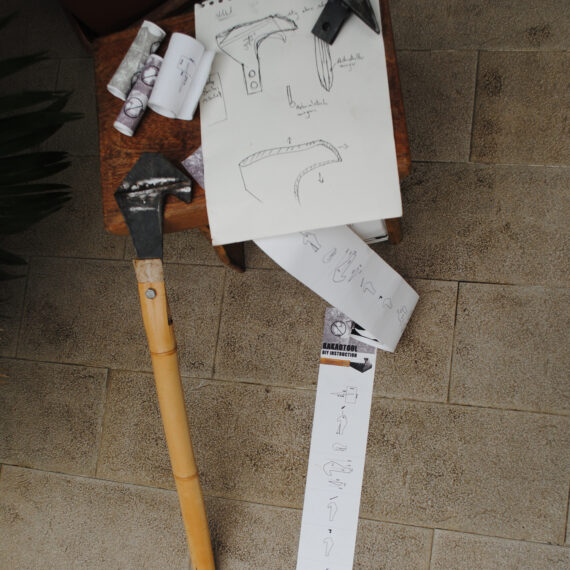

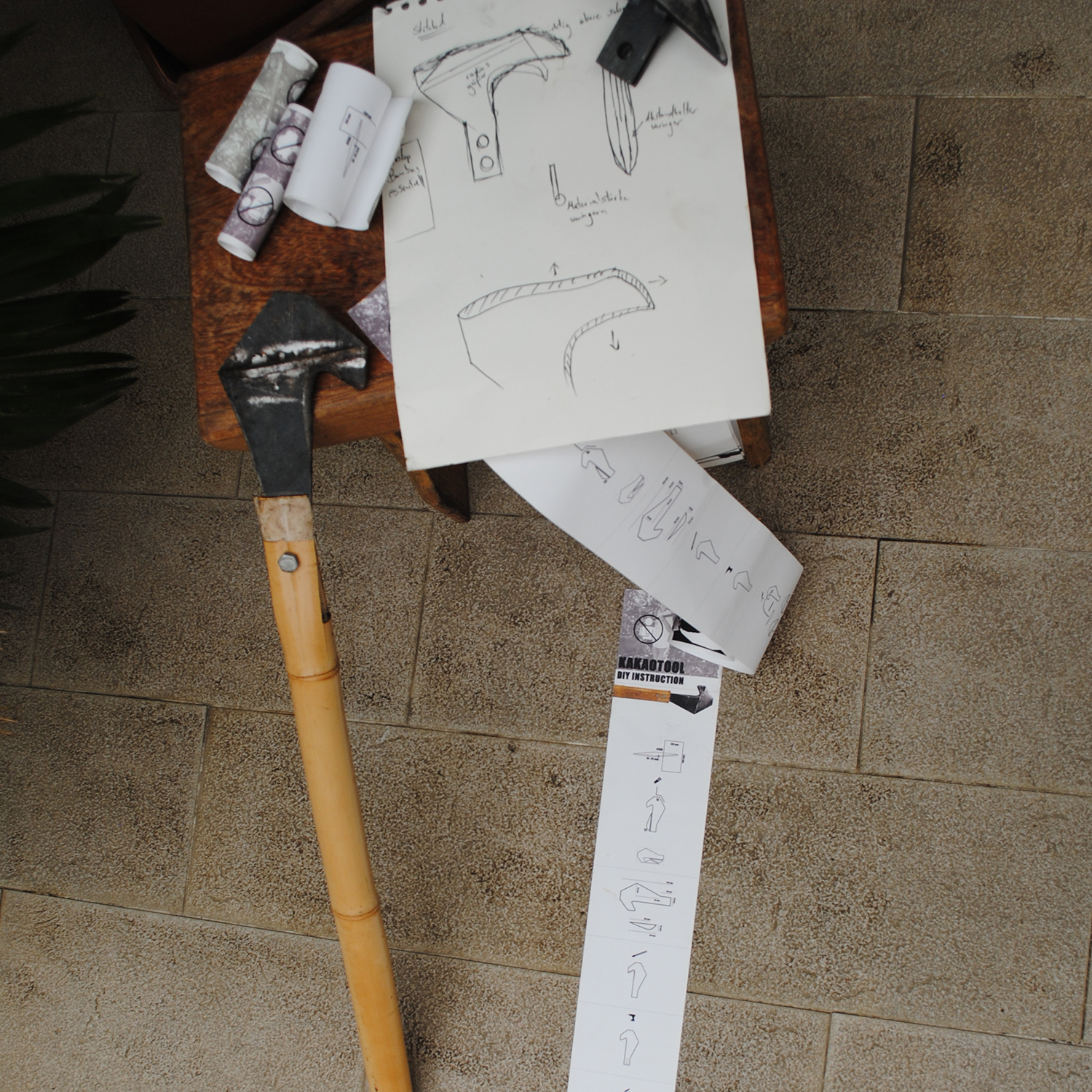

This tool development got initiated in an overarching project. Bösöppe e.V., the University of Art and Design Offenbach am Main and the Agricultural Ministry of Equatorial Guinea established a cooperation to make the long-time undervalued field of cacao small farming more attractive to work in. This way the project aimed to deliver professional opportunities to the citizens of Bioko island.

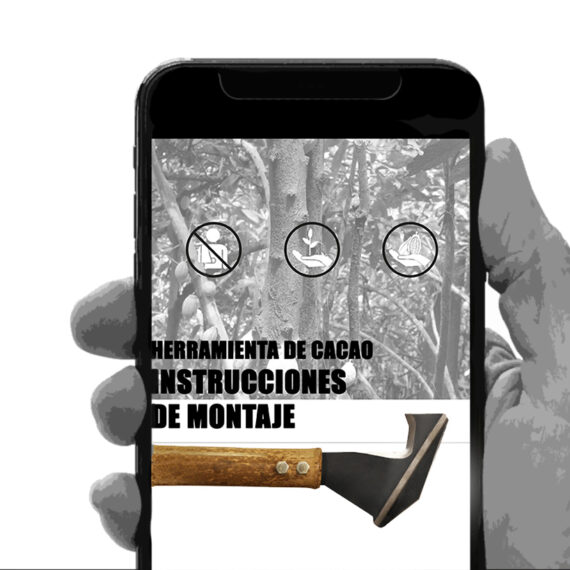

The project took a holistic approach and developed a way of distributing the products, creating new products, making the actual work more appealing, and connecting the small farmers. The first step got developed in Offenbach, consulted by Bösöppe e.V. and then further on-site with the farmers.